Moisture is a hazardous thing, especially in the presence of oxygen, as insulation of transformer is at risk. Each time the level of moisture gets double in a transformer, the insulation life is cut by one-half. Take the life of transformer like the life of a paper. The purpose of the paper is to prevent moisture and oxygen. If a service-aged transformer is rated less than 69 kV, results of up to 35 ppm at 60 degrees Celsius temperature is acceptable. As per leading power transformers manufacturers, transformers rated more than 230 kV should not have moisture more than 12 ppm at 60 degrees Celsius.

During the time of energizing of the transformer, water starts to migrate to the coolest part of the system and the site of the largest electrical stress. Temperature of the oil plays vital role in deciding how the water distributes itself between the paper and oil. While preparing for tests, when you take the oil sample, you must record oil temperature from the oil temperature gauge placed at top.

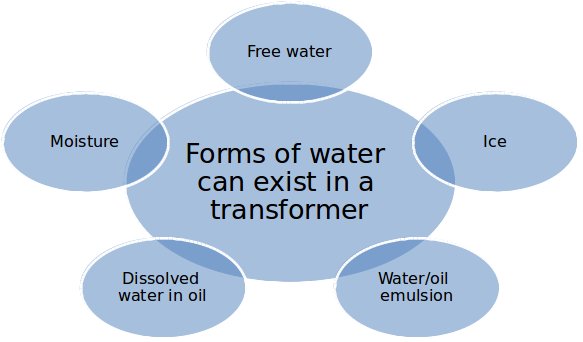

How water enters? Moisture can be inside the insulation when factory delivers it. In case the transformer is opened for further inspection, there are chances when insulation absorbs moisture from the environment. Even if there is any leakage, moisture can enter in the form of humidity or water. It can also formed by insulation degradation when transformer gets older.

Gaskets are the most common moisture ingress points between bushing bottoms and the top of transformer and the pressure relief device gasket. Small oil leakage points also help moisture to enter inside the system and thus, it is necessary to repair small oil leaks to prevent moisture coming inside the transformer and ruin its insulation.

To extend the life of the power transformer, manufacturers find that by keeping the transformer dry and free from oxygen can help a lot. Oxygen and moisture amount can degrade the insulation of transformer at faster rate as compared to sludge, acids and other contaminants.

The option of drying the transformer can be bit costly for user, so it is suggested to consult professionals prior making final decision. But when it comes to life of the transformer, drying process is less expensive than bearing cost of transformer repairing and replacement. This is what high power transformers manufacturers think. Do you think the same? Share your reviews with us.

No Comments

Leave a comment Cancel