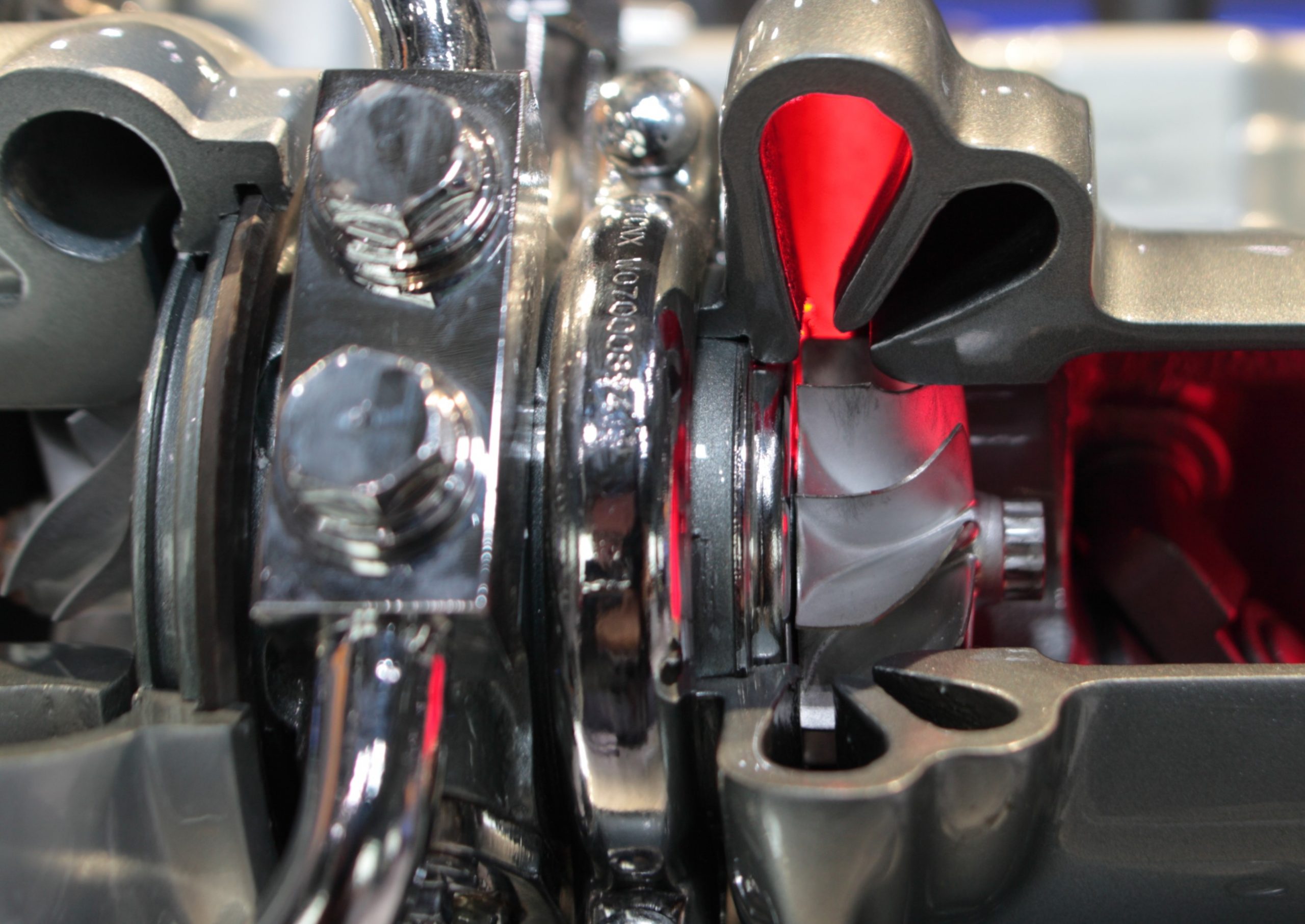

Car enthusiasts are eager to put turbochargers into their performance cars. It’s a good thing to know how turbochargers work. The system compresses air that enters the cylinders inside the engine. Because more air is forced into the cylinder, the engine delivers higher burning power. Normally, turbochargers can force 50 percent more air into the cylinders. Due to a degree of inefficiency, the engine will obtain only up to 40 percent of increased performance. Turbocharger is connected to the exhaust manifold and the system is powered by the exhaust gasses. Two primary components of turbochargers are compressor and turbine. The exhaust gas is directed to the turbine blades of the turbochargers, causing them to spin. The turbine is connected by a long shaft to a compressor. Both turbine and compressor wheels rotate, so they are able to draw in fresh air from the intake into the cylinders of the engine. The more air that’s forced into the engine, the higher the performance that we will get. However, it is possible that the turbocharger wheels to rotate very quickly, beyond the capability of the whole system. Wastegate detects the pressure and it releases a portion of the exhaust gas before touching the turbine, effectively limiting the rotation.

One important fact to consider is that air heats up when it’s compressed. However, when air heats up it will become less dense, due to their rate of expansion. It means that the act compressing the air will result in expansion effect, which counteract one another. As solution, turbochargers have cooling component, so pressured air can stay compressed, so denser air can enter the cylinders. Turbo lag is one consideration when using turbocharger. It means that when we push down the accelerator pedal, we will notice a short delay before boost of power kicks in. This happens because it takes time before dense air can be forced to the cylinders. Smaller turbocharger system will shorten the delay. Ceramic and other lighter materials could also solve delay problems. Light and small-sized turbocharger should be able to minimize lag and provide quicker boost. However, massive boost could be delivered only by large turbocharger. There are different configurations that we may use. As an example, we may use twin turbo system, that’s consisted of one smaller turbocharger and another bigger one.

The smaller turbocharger quickly provides lighter boost and when more power is needed, the larger turbocharger will provide additional power. Twin turbo system is more efficient, because the larger turbocharger doesn’t operate when small amount of boost is needed. Turbochargers are useful when we need more torque and horsepower. With proper configuration, we should still be able to maintain cleaner emission and acceptable fuel costs. When choosing a turbocharger, we should make sure that it has simple and reliable design. Some models only add slight increase in weight, so there’s no significant penalty in performance. To further improve engine performance, ECU remapping can be implemented. This allows us to gain higher fuel economy, smoother power delivery and sharper throttle response.

No Comments

Leave a comment Cancel